Exploring Advanced Lightweight Steel Frame Construction: The Future of Building Efficiency

Aug 19,2025

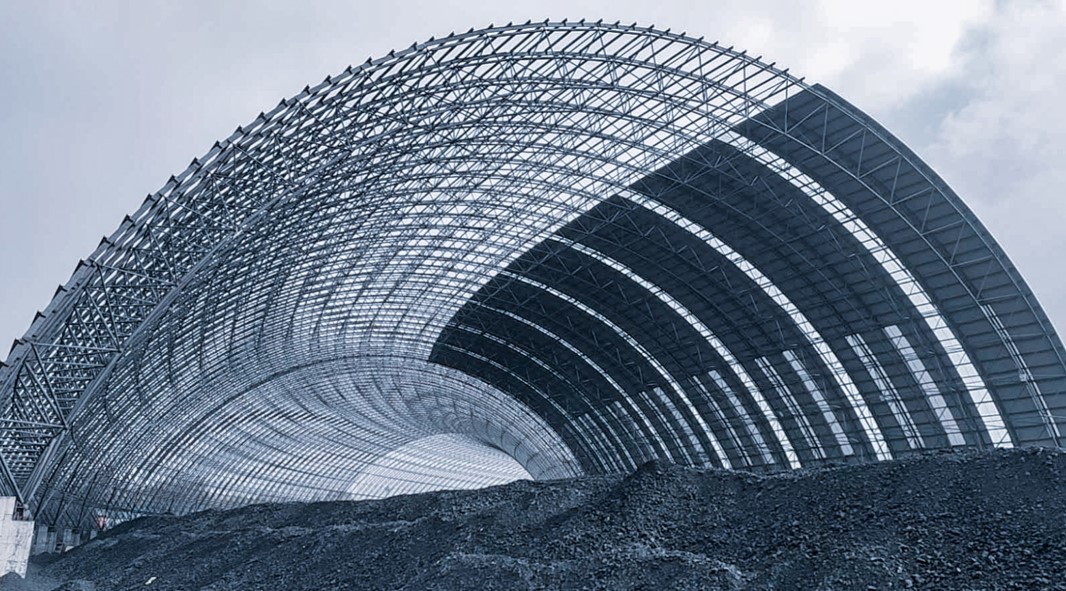

Advanced lightweight steel frame construction represents a significant evolution in the building industry, particularly within the realm of construction materials and structural components. This innovative method utilizes high-strength steel that is both robust and lightweight, resulting in a variety of benefits that make it increasingly popular among architects and builders.

One of the primary advantages of advanced lightweight steel frame construction is its improved strength-to-weight ratio. By utilizing advanced materials and engineering techniques, this construction method allows for the creation of structures that are not only strong but also significantly lighter than traditional building materials. This reduction in weight translates into lower transportation costs, easier handling on-site, and reduced loads on foundations, which can lead to further cost savings during the construction process.

Another key benefit is the increased design flexibility it offers. The inherent properties of lightweight steel enable architects to explore more innovative designs and complex configurations. This flexibility means that buildings can be both aesthetically pleasing and functionally efficient without compromising safety or durability. Additionally, the use of steel frames allows for larger open spaces within buildings, as the need for load-bearing walls is minimized.

Sustainability is another essential aspect of advanced lightweight steel frame construction. Steel is 100% recyclable, which contributes to the reduction of waste in landfills. Furthermore, the manufacturing processes for lightweight steel are increasingly being optimized for energy efficiency, allowing for a lower carbon footprint throughout the construction lifecycle. This aligns with global initiatives aimed at promoting sustainable building practices and reducing environmental impact.

Installation time is also significantly reduced when using advanced lightweight steel frames. Traditional construction methods often require extensive labor and time for assembly, whereas lightweight steel frames can be prefabricated off-site and quickly assembled on-site. This not only accelerates the construction schedule but also minimizes disruptions to the surrounding environment and community.

Moreover, lightweight steel frame structures demonstrate excellent performance in terms of durability and resistance to various environmental factors, such as pests, fire, and severe weather conditions. This resilience contributes to lower maintenance costs over time, making it a smart investment for builders and property owners alike.

In summary, advanced lightweight steel frame construction is revolutionizing the building industry by combining strength, design flexibility, sustainability, and efficiency. As the demand for innovative building solutions increases, this construction method is likely to play a crucial role in shaping the future of architecture and structural engineering. By harnessing the potential of lightweight steel, professionals in the construction sector can create structures that meet the needs of modern society while promoting a sustainable future.

One of the primary advantages of advanced lightweight steel frame construction is its improved strength-to-weight ratio. By utilizing advanced materials and engineering techniques, this construction method allows for the creation of structures that are not only strong but also significantly lighter than traditional building materials. This reduction in weight translates into lower transportation costs, easier handling on-site, and reduced loads on foundations, which can lead to further cost savings during the construction process.

Another key benefit is the increased design flexibility it offers. The inherent properties of lightweight steel enable architects to explore more innovative designs and complex configurations. This flexibility means that buildings can be both aesthetically pleasing and functionally efficient without compromising safety or durability. Additionally, the use of steel frames allows for larger open spaces within buildings, as the need for load-bearing walls is minimized.

Sustainability is another essential aspect of advanced lightweight steel frame construction. Steel is 100% recyclable, which contributes to the reduction of waste in landfills. Furthermore, the manufacturing processes for lightweight steel are increasingly being optimized for energy efficiency, allowing for a lower carbon footprint throughout the construction lifecycle. This aligns with global initiatives aimed at promoting sustainable building practices and reducing environmental impact.

Installation time is also significantly reduced when using advanced lightweight steel frames. Traditional construction methods often require extensive labor and time for assembly, whereas lightweight steel frames can be prefabricated off-site and quickly assembled on-site. This not only accelerates the construction schedule but also minimizes disruptions to the surrounding environment and community.

Moreover, lightweight steel frame structures demonstrate excellent performance in terms of durability and resistance to various environmental factors, such as pests, fire, and severe weather conditions. This resilience contributes to lower maintenance costs over time, making it a smart investment for builders and property owners alike.

In summary, advanced lightweight steel frame construction is revolutionizing the building industry by combining strength, design flexibility, sustainability, and efficiency. As the demand for innovative building solutions increases, this construction method is likely to play a crucial role in shaping the future of architecture and structural engineering. By harnessing the potential of lightweight steel, professionals in the construction sector can create structures that meet the needs of modern society while promoting a sustainable future.

Contact Us

E-mail :

183597530@qq.com

WhatsApp:

+86-13810577811

Address:

No. 4 Fengzhi Road, Binhe New District, Baotou Rare Earth High tech Zone, Inner Mongolia Autonomous Region